Fixture solutions solve complex EV battery assembly challenges and deliver 300% uplift in production for luxury sportscar manufacturer.

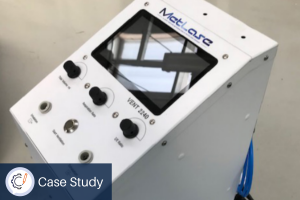

MetLase demonstrates the power of adding sensors to existing industrial processes, and the positive impact of harvesting live in-process data can have, to improve the …

The MetLase Smart Bench solves the challenges faced by manufacturers across multiple sectors with almost all their manual assembly processes.

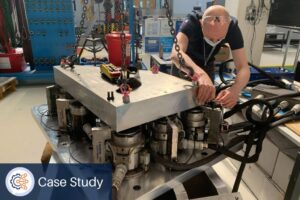

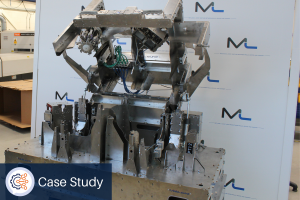

MetLase were asked to develop an alternative fixture solution, with cycle time reduction and reduced variation as primary objectives.

The welding process often requires inert gases to improve the quality of the weld. Gas shields provide a controlled atmosphere, protecting the weld from atmospheric …

In the early stages of the COVID-19 pandemic, a worldwide shortage of ventilators led the UK government to issue a call to arms to the …

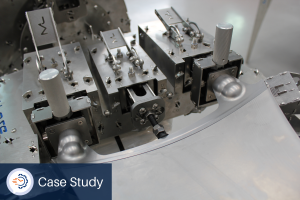

The customer currently uses the New Generation Fuel System blow molding process to produce plastic fuel systems. Due to the complicated nature of this process, …

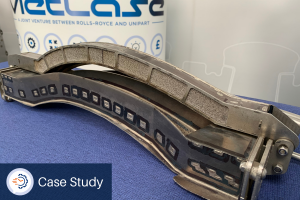

Fast make delivery of R&D NGV sealing strips, at lead-times previously unobtainable.