Turbine Nozzle Guide Vane (NGV) Sealing Strip Manufacture

Fast make delivery of R&D NGV sealing strips, at lead-times previously unobtainable.

Introduction

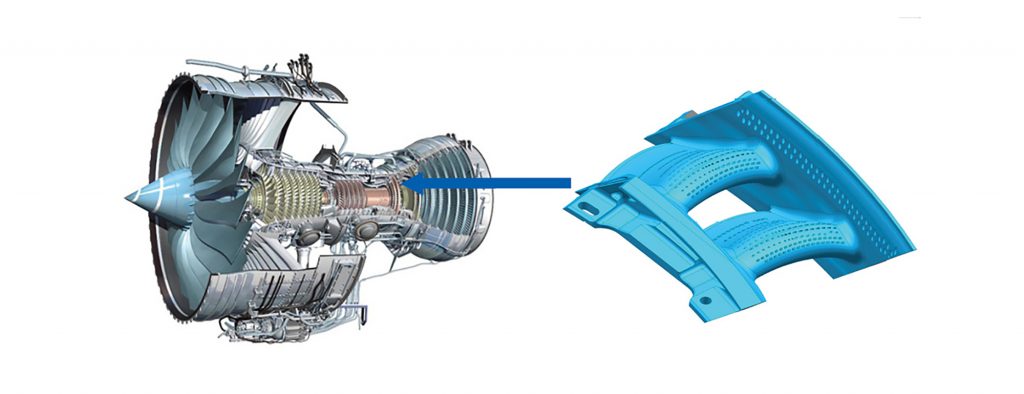

The turbine at the back of a jet-engine is a high-pressure, high temperature component which extracts power from the combusted gases. NGV’s are assembled using highly tolerance sealing strips that prevent undesired gas leakage.

MetLase was approached by the customer to manufacture two R&D engine sets of turbine NGV seal strips traditional manufacturing routes had lead-times that would result in engine test programme slippages.

Solution

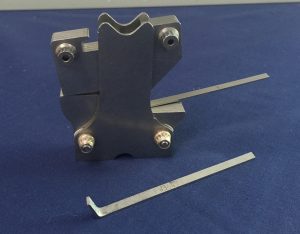

MetLase was able to employ its laminate press-brake tooling technology to quickly create the precise bend iterations required in the material, vastly reducing the usual lead time on these components.

Benefits

Two R&D engine sets were delivered within six hours of receiving the required geometry and specifications. This rapid delivery prevented an estimated 2 to 3-month slippage of the engine test programme and the associated costs incurred.

Summary

Adaptability: Quick turnaround of bend iterations through MetLase laminate press-brake tooling

Fast Make: 2 R&D engine sets delivered within 6 hours of geometry receipt

Delivery: Rapid delivery prevented estimated 2-3 month slippage of engine test programme