Optimise. Digitise. Transform.

Our digitally-led & mechanical manufacturing solutions provide added value

through rapid problem solving for high value manufacturers

What do we bring to our Customers?

Innovation

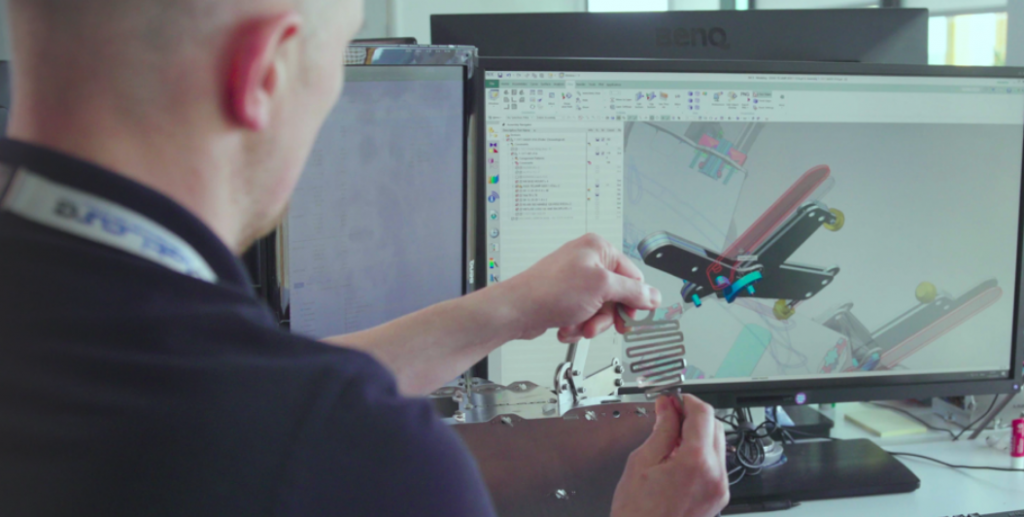

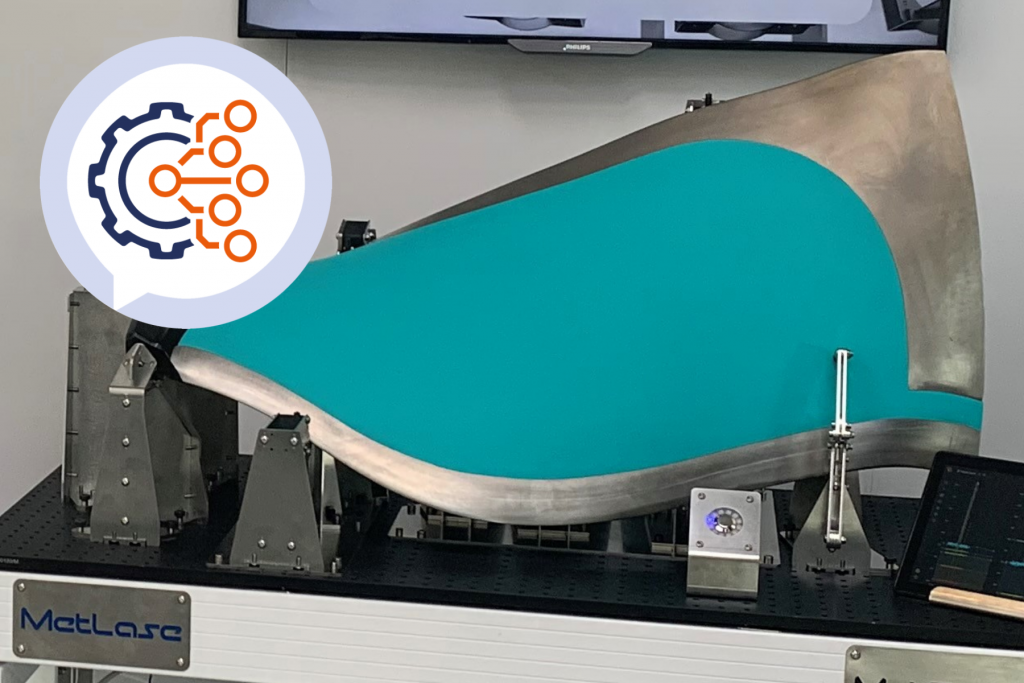

MetLase has developed a rapid tooling and prototyping process that embraces all electro and mechanical elements of design, robust software testing and a range of patented in-house technology applications.

Applied Digital Technologies

Connect, optimize, and scale your digital manufacturing applications using MetLase’s patented technology solutions to generate, harvest and display information in real-time that is actionable and makes customers more agile and responsive to their own clients.

Multi-disciplinary Expertise

MetLase has built a multi-disciplinary engineering team capable of delivering custom design, innovation and operational efficiencies.

MetLase Digital Academy

Our Digital Academy is a FREE virtual learning platform where you can learn from our skilled and experienced engineers. We cover the full spectrum from the fundamentals of fixturing, tooling and workholding, to the latest connected and integrated Smart Factory technologies.

What do our clients use MetLase Solutions for?

Every industry faces its own set of challenges that can require specialist support. MetLase has partnered with leading manufacturers from across the globe to transform their operations using mechanical and digital manufacturing solutions.

Accelerate development

Our rapid development time can increase efficiency, reduce design time, and reduce prototyping costs.

Improve your OEE

Digital manufacturing can discover previously unmeasured KPIs to find hidden inefficiencies.

Customised design

Improve product complexity using a customised solution developed to your specification.

What our Customers say about Us

Reach Your Digital Manufacturing Goals with Us

Technologies are improving, changing and developing at an ever-accelerating rate. This presents significant challenges to manufacturers, but also a significant opportunity. MetLase can support your business wherever you are on your journey of technology adoption. Whether this is the first implementation of digital technology, or fully automated and optimised manufacturing cell, or even factory.