Rapid Reaction

Reducing lead times and increasing design flexibility are just two of the benefits offered by rapid tooling, a manufacturing process proving increasingly popular with companies looking to improve efficiencies and be first to market with new products. Richard Gould, Business Development Manager of MetLase, explains how his firm are leading the rest of the world in this approach.

Speed is of the essence. It’s a popular phrase and one taking increasing precedence in this globally competitive manufacturing world firms find themselves in. Whether it’s supplying just-in-time for car manufacturers, developing safety critical components for aerospace or being first to market with a new product, the demand for shorter lead-times is growing.

The design and manufacture of tooling is one sector of industry that, to date, has been immune to this change, with a lot of companies happy to factor in many months for the development and delivery of fixtures used in assembly, machining and inspection. Well that could be about to change thanks to the efforts of a Yorkshire-based manufacturing specialist that has introduced a transformative approach to the rapid development of tooling, reducing production time from months to weeks and, in some instances, just a few days.

Transforming the tooling landscape

MetLase, a joint venture between Rolls-Royce and Unipart, is rewriting the rule books when it comes to this critical discipline of engineering, and industry is responding with a surge of orders.

Over the last twelve months, the business has developed an approach harnessing the design skills of a 25-strong engineering team and unique joining solutions that replace the traditional welding process – the latter is apparently top secret and not even customers are given all of the details.

This is reinforced by significant investment at its AMP Technology Centre home to give its experts access to state-of-the-art laser cutting and press brake capabilities.

“The traditional tooling approach is that you take a massive block of material and then you machine away the bits you don’t want to form the tool,” explained Richard Gould, Business Development Manager at MetLase.

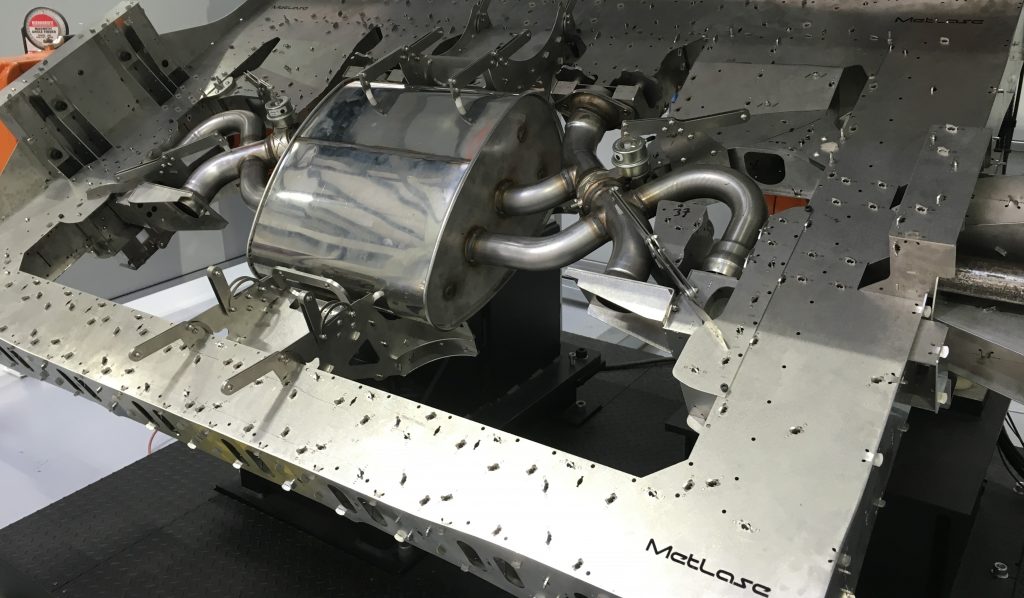

“We take a different stance, basically laser cutting sheet metal, usually stainless steel or titanium, into lots of different elements. These are then joined together to form the tool using our very own manufacturing technique, removing the need to weld them together and the distortion that usually comes with this approach.”

He continued: “Everything is controlled ‘in-house’ at MetLase and that’s another big benefit as we control the entire process. We have all the technology we require, we have the engineering talent and we are always adding to our standardised feature library and parametric modelling system that will allow us to instantly access formula for creating tools for specific applications.

“All of this means we are able to work with customers to reduce lead times to weeks, meaning the client has more time to iterate their component design before signing off the tooling.

“As well as the time saving, our service can also help mitigate massive financial costs associated with last minute changes.”

Reducing lead times

MetLase has already completed a number of high-profile projects using its rapid tooling development.

This includes creating a pipe fixture in less than 24 hours, using parametric modelling to modify a composite wing fixture for F1 in just 12 hours and responding quickly to a premium British automotive manufacturer’s styling department change that saw it accommodate quad pipes instead of twin.

The company, which played a key role in the VentilatorChallengeUKConsortium, has also just delivered its largest ever tool, measuring 4 metres in diameter and capable of holding a component 2 metres tall.

Despite the scale of the project, manufacturing sign-off and delivery was completed in just one month. Previously, the client would have expected it to take half a year.

Richard picked up the story: “Interest has come from automotive and aerospace initially, but we are now seeing other sectors, such as construction and medical, exploring rapid tooling and the benefits that can give them.

“Our engineers work best when we have a blank sheet of paper in front of us. This gives them the freedom to listen to the client and what they want the tooling to achieve and then develop a solution that surpasses the brief.

“The MetLase approach means the design engineer you first talk to will actually oversee the entire project, often completing the manufacturing of the tool themselves. Unlike traditional processes, we can also test ideas out relatively quickly by developing prototype tooling at little cost before agreeing full production.

“It can also be a crucial lifeline for companies looking to ramp up production or create new manufacturing cells quickly. Our rapid tooling service means we can take that headache away from them, leaving them free to concentrate on other business critical activities safe in the knowledge their tool or tools will arrive weeks ahead of when they were initially expecting.”

Competing with 3D printing

There has been a lot of talk about this type of manufacturing being faster than 3D printing, and as Richard is quick to point out, in many respects, it is far quicker.

However, he also cites the fact each process is different and to compare the two manufacturing methods is generally very difficult. In fact, MetLase itself uses additive layer components within its solutions where it fits, usually in non-critical areas.

“It’s an interesting argument to have,” admitted Richard. “I prefer to see them as different and sometimes complementary options, each with their own benefits and cost savings. What we have done is moved rapid tooling into the realm of conversation with 3D printing, and this has only been possible by the speed with which we can deliver.

“We wouldn’t have been having this conversation 12 months ago.”